Nest Coffin

◼ An ecological coffin for the French market

◼ 2022

◼ with Clemence Nollim

Challenge

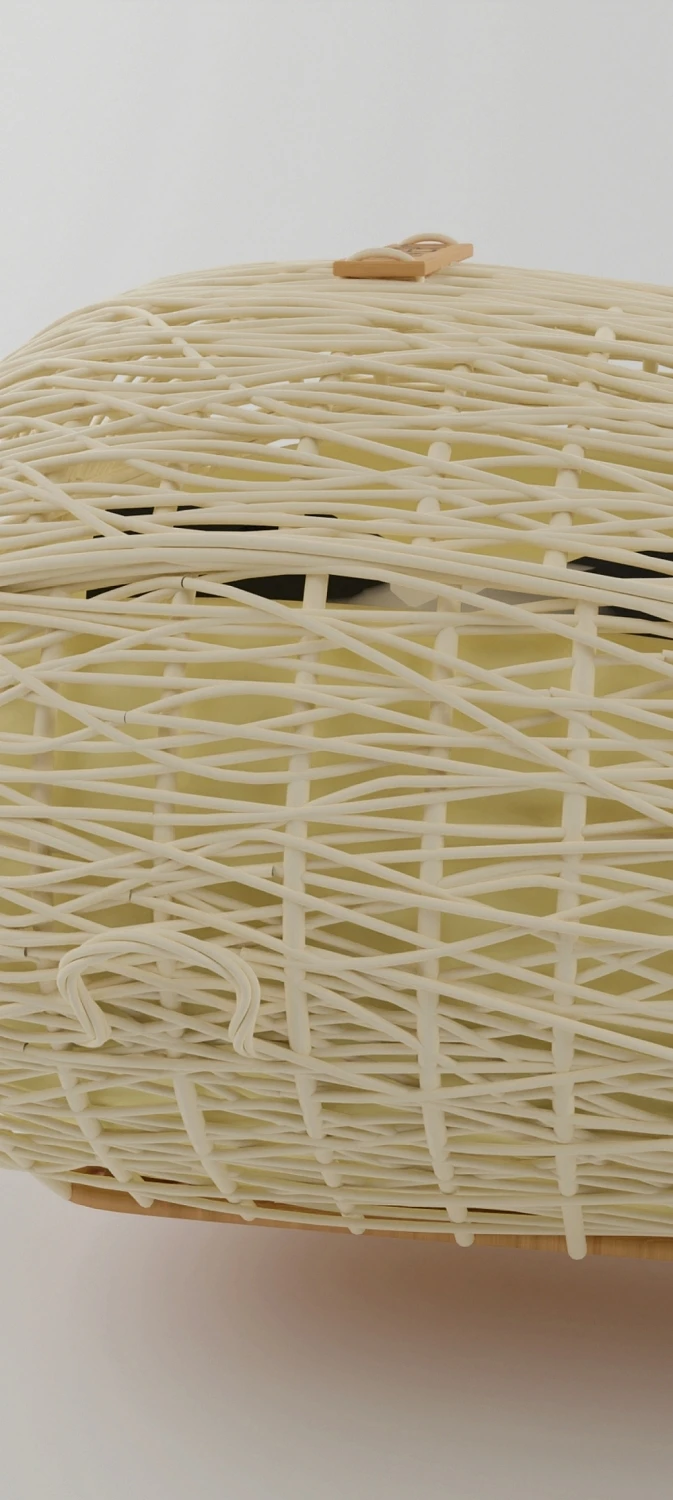

We were tasked with developing a coffin for the eco-conscious consumer in the French market. This required the use of biodegradable materials that comply with the relatively strict French regulations concerning impermeability and structural integrity. The typical coffin, made out of wood or wood-substitutes, contains resins and lacquers that are toxic to bury or burn, so the partner asked that we develop aesthetically pleasing alternatives.

Research

After experimenting with different materials, we settled on wicker, which is relatively inexpensive, produced sustainably in France, and is 100% biodegradable. To verify our research and acquire a better understanding of the material, we took a trip to Villaines les Rochers, a town specializing in the production of wicker goods. There, we spoke to several cultivators and artisans, all of whom confirmed that the material possessed the qualities necessary to meet the needs of the project.

Ideation

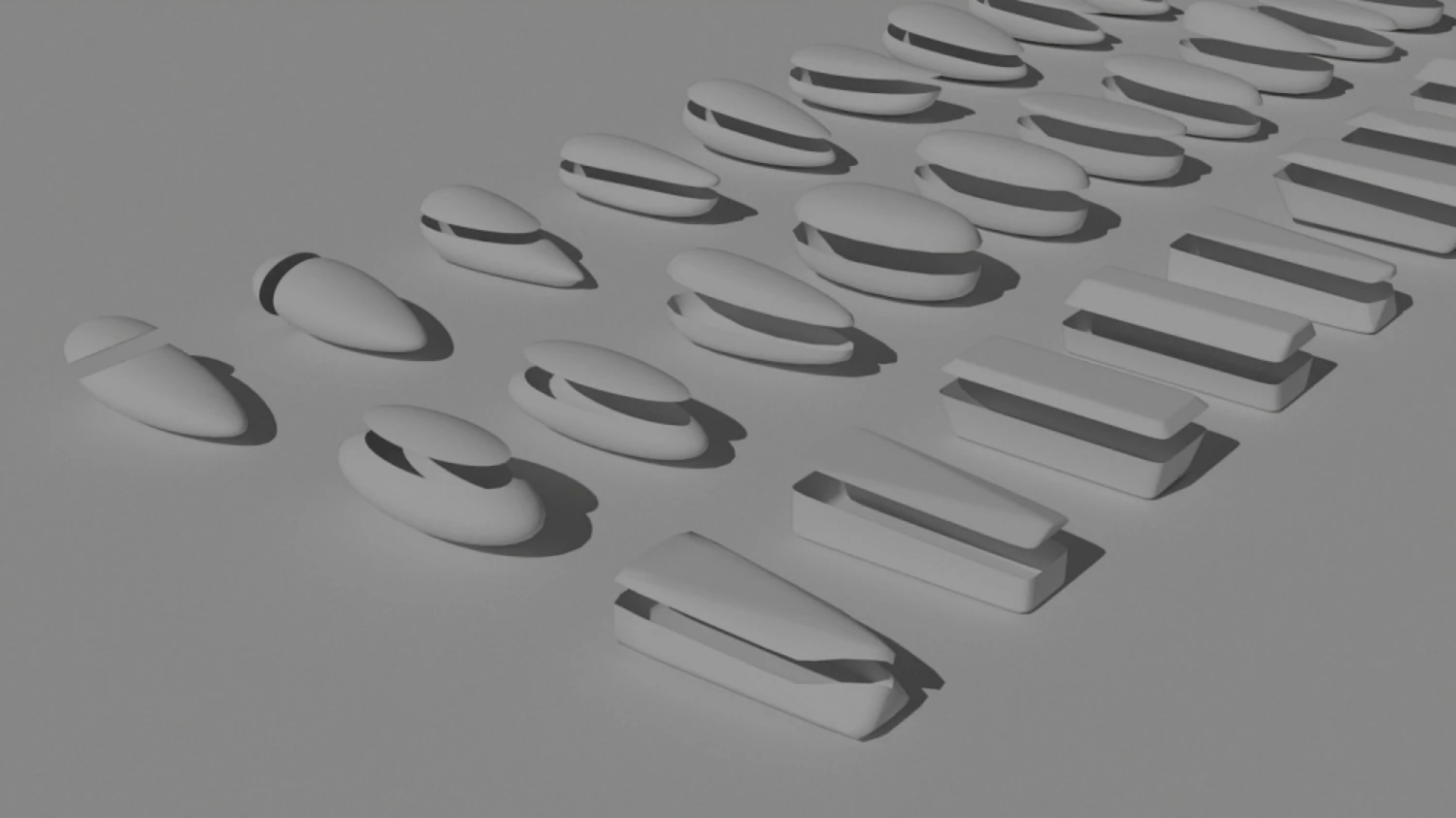

Taking inspiration from bird nests, we aimed to create a form that corresponded to the material. In addition, we added a layer of recycled wool felt coated in biodegradable wax to meet the regulatory requirement of impermeability, as well as a “cloud” of raw wool to absorb moisture. A base of untreated beechwood was added to ensure adherence to structural regulations. All materials were chosen on the basis of their local and sustainable production.

Creation

We took a second trip to Villaines les Rochers to work alongside a craftsman who taught us the necessary techniques to create the samples, testing various types of wicker and weaves in the process. We also conducted impermeability tests using different kinds of natural wax, eventually settling on olive wax for its low price, sustainable production, and relatively high melting point.

Result

We produced a cross section of the coffin at scale, a 3D render of the entire coffin at scale, and two samples at 1/5th scale to represent two ends of a spectrum of aesthetic and structural possibilities. Each sample was submitted to the stress testing necessary to ensure compliance with regulations.

e-steel

black diamond conversions

estuaire

design of the afterlife

tich tech

back to top

e-steel

black diamond conversions

estuaire

design of the afterlife

tich tech

back to top